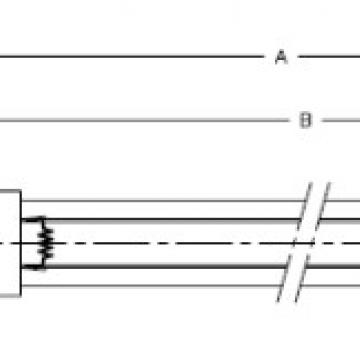

Bóng đèn tia cực tím GPH HA 1554 T10L 500W

Amalgam UV lamps (also known as high output, low-pressure lamps) contain mercury like other UV germicidal lamps, but it is in the form of an alloy with another metal – creating an amalgam.

Amalgam UV Lamps

This means the mercury is fixed to amalgam spots on the lamp body or contained in amalgam pellets, altering the way the lamp works in two ways. Firstly, the amalgam spots or pellets work as a pressure regulator, absorbing and releasing mercury as the lamp pressure fluctuates. As a result, the lamp’s UV output remains constant and will not be affected by changes in the temperature of the water or air around it. Secondly, the amalgam allows the lamp to operate effectively at a higher temperature, so that the lamp can be powered at a higher wattage and therefore generate more UVC.

The process of manufacturing amalgam lamps is labour intensive and more expensive than that of low or medium pressure UV lamps, so the lamps tend to sell for a higher price. However, the increased lifetime of an amalgam lamp means a good return on investment in the long term.

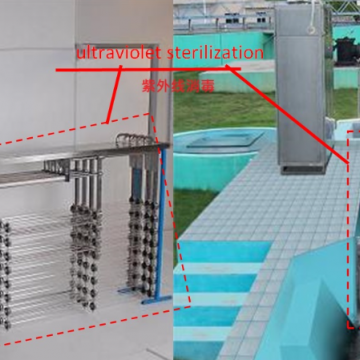

Amalgam lamps are suitable for the disinfection of liquids, air and surfaces, but the high temperatures generated by running them at high power can cause issues if they are used in very still or stagnant air or water.

TAG: ,Chia sẻ:

TwitterCó Thể Bạn Quan Tâm

BÓNG ĐÈN UV GHO 48T5L/5/105W

Xem chi tiếtBóng đèn tia cực tím

Xem chi tiếtChính sách bán hàng

Xem chi tiếtVận chuyển

Miễn phí nội thành Hà Nội

Thanh toán

Thanh toán online hoặc COD

Đổi trả

1 đổi 1 trong 30 ngày

Giờ mở cửa

8 giờ sáng - 17 giờ chiều